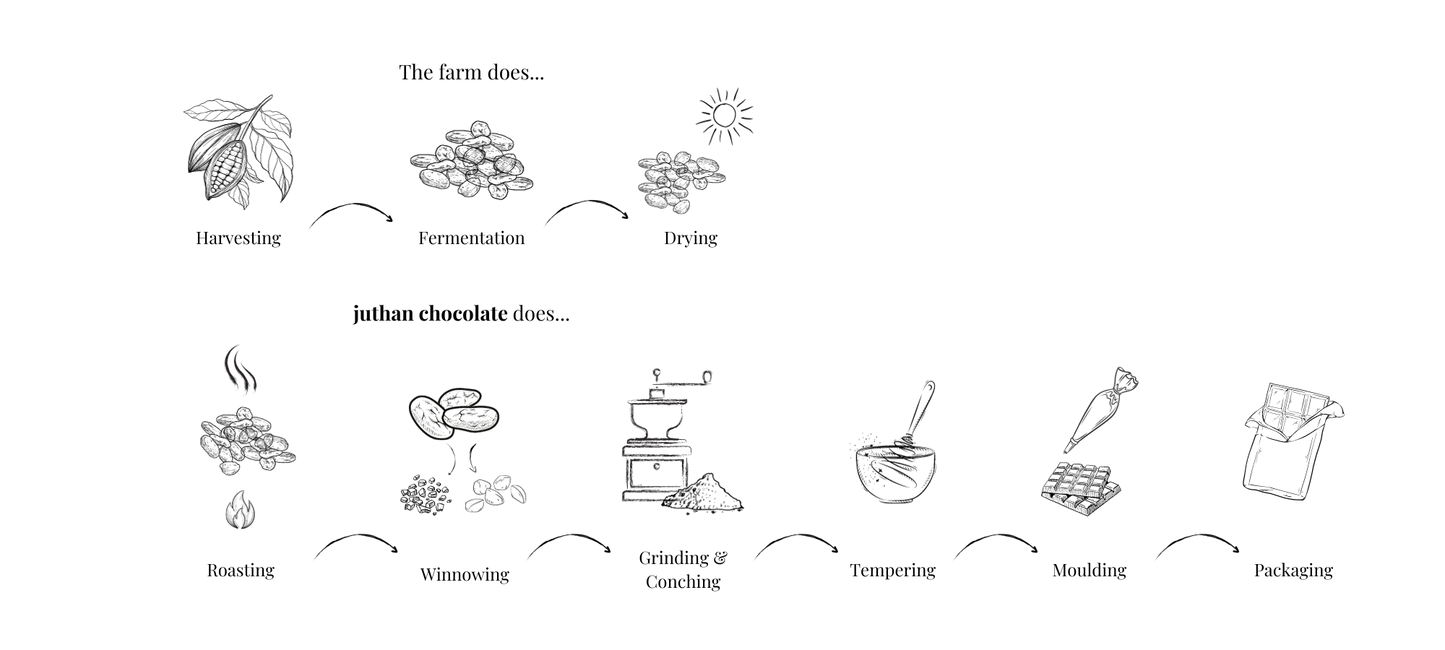

Unlike the vast majority of chocolate brands you buy in-store and online today which import and sells ready-made chocolate, we opted to create a fuller and richer experience by producing our own chocolate from the raw bean to the final chocolate bar (bean-to-bar chocolate)

Understanding the complexities of creating bean-to-bar chocolate creates an appreciation for the craftsmanship and effort involved when producing our chocolate. Our attention to detail at every step of this process ensures we deliver unsurpassed quality with every chocolate bar we sell.

|

|

Growing and harvesting The very first thing to understand about chocolate is to know there is not just a single cacao plant variety. Just like grapes there is a whole host of different cacao bean varieties used to create chocolate. Each variety offers a unique flavour experience. The four main varieties are:

In addition to the different varieties, the region where the beans are grown also influence the flavour, the same cacao variety grown in Madagascar and Peru will have differences in the flavour of the chocolate produced. Some of the top cacao producing countries are:

juthan chocolate has a single origin chocolate from Peru with a mixed cacao variety to achieve a consistent and balanced flavour profile. |

|

Fermentation Once the beans are harvested, they pods are cut open and the beans are extracted from the pods. At this stage the beans are covered in a white mussy casing and are extremely bitter, trying to eat the bean at this stage will leave you with an exceptionally unpleasant taste in the mouth. All the beans are collected and placed in wooden boxes and left to ferment. The fermenting is a very crucial stage in the journey to become a cocoa bean. Farmers constantly monitor the temperature of the fermenting beans and stir occasionally to introduce oxygen to help the bacteria, enzymes, and yeast work their magic to start developing the chocolate flavour. The duration which cacao beans are left to ferment also has an impact on how the chocolate flavour develops. Beans with shorter fermentation periods has a more bitter, smokey and stronger cocoa taste than beans left to ferment for longer which tend to be more creamy, sweet and less pronounced cocoa flavour. |

|

|

Drying Another step in the process that impacts the eventual taste is the drying process. Beans left to dry more slowly has a fuller more fruity flavour vs beans dried quickly who tend to lose some of the flavour of the beans Once drying is complete the beans are packed and sent to the chocolate producers. At this stage we see the farmer already influenced the final chocolate flavour a great deal and why it is necessary to go through a rigorous bean selection process. |

|

Roasting This is where our journey to produce exceptional chocolate begins. Roasting has 3 main functions:

The longer you roast you beans the less acidic and bitter they become by reducing the concentration of volatile acids. Simply put, the longer you roast your beans the more they taste like chocolate. Different chocolatiers have different approaches to roasting, some do higher temperatures but shorter roasting times, other roast longer at lower temperatures. In keeping with the slow drying process after fermentation where drying for longer is better, we at juthan chocolate slow roast our beans at a lower temperature of about 125C for about 40 minutes. This develops a well-balanced creamy, sweet, and smoky chocolate flavour. Interesting reference name change: After roasting we talk about cocoa beans and not cacao beans. Cacao refers to cacao beans that have not been roasted where cocoa beans are roasted cacao beans

|

|

|

Winnowing

Winnowing is the process of crushing the whole cocoa beans to separate the cocoa nibs (crushed cocoa beans) from the hull and then extracting the undesired hull from the nibs. To ensure the cleanest nibs, we cycle our nibs through the hull extraction process twice. We do lose some cocoa nibs in this process but it results in a much more pure batch of nibs which in turn helps to create a better quality chocolate product. |

|

|

Grinding & Conching This stage of our chocolate production is critical to achieve juthan chocolate's silky smooth texture and why our chocolate stays at this stage for 3 days. The cocoa nibs are fed into a device called a melanger where the nibs are ground between two granite rollers for 3 days. It is also at this stage where ingredients like milk (where applicable) and sugar is added to be ground with the nibs. This ongoing process of grinding and churning the chocolate ingredients is referred to as conching. Our tongues can detect extremely small particles. In typical chocolate the conching is done for less than a day which results in a chocolate with a gritty texture. Running our conching process for 3 days we are able to achieve that silky smooth texture our customers have come to love and appreciate. Interesting fact: Chocolate and water are enemies and do not mix at all. This is the reason we cannot simply dissolve sugar and other powdered ingredients to be mixed in with crushed cocoa nibs, we literally have to crush all ingredients to achieve those smooth textures. |

|

Tempering Tempering is the process of controlling the heating, cooling, and reheating chocolate to allow desired crystals to form that gives quality chocolate the beautiful shine and crisp snap when you break off a piece. There are 6 different types of crystals in chocolate and each of these have a different melting and crystallization temperature. Chocolate is very temperamental and to successfully temper chocolate you have to follow the temperature curve exactly with very little margin for error; too cold you get crystals that form where the chocolate immediately melts when you touch it, too hot and the ideal crystals never form leaving you with a soft textured chocolate. Many producers use lecithin to help with chocolate tempering as it greatly simplifies this process but lecithin is an additive we that give your chocolate a waxy taste. We only use cocoa nibs and cocoa butter in our bars which make the process more complex and expensive but does yield a superior product. |

|

|

Moulding This is the last step where we pour our tempered chocolate into the molds for our various products. At this stage, the room and cooling temperatures need to be controlled to be within specific ranges. If it's too cold, the chocolate sets too quickly, while if it's too hot, cocoa butter separation from the cocoa powder can occur. Both hot and cold temperatures can cause chocolate bloom, which is the white streaks you sometimes see on older chocolate. While there is nothing wrong with the product, it is not visually appealing. |

|

Wrapping Once our chocolates are set we wrap each bar by hand. The many wrapping gives us the opportunity to spot imperfections and reject the chocolate. Rejected bars are re-tempered and re-moulded to be used in a future batch. |

|

Go on, indulge yourself - you deserve it! :)

Remember to follow us on facebook and instagram to stay in touch and follow our amazing chocolate journey.